The Best Practices in Cold Chain Management

It’s no surprise that the industries of pharmaceutical, food and medical around the world are highly reliant on the cold chain. After all, no suppliers would like to compromise their shipment of temperature-sensitive goods before they reach the market.

As a result, not to mention, the cold chain supply sector is persistently evolving.

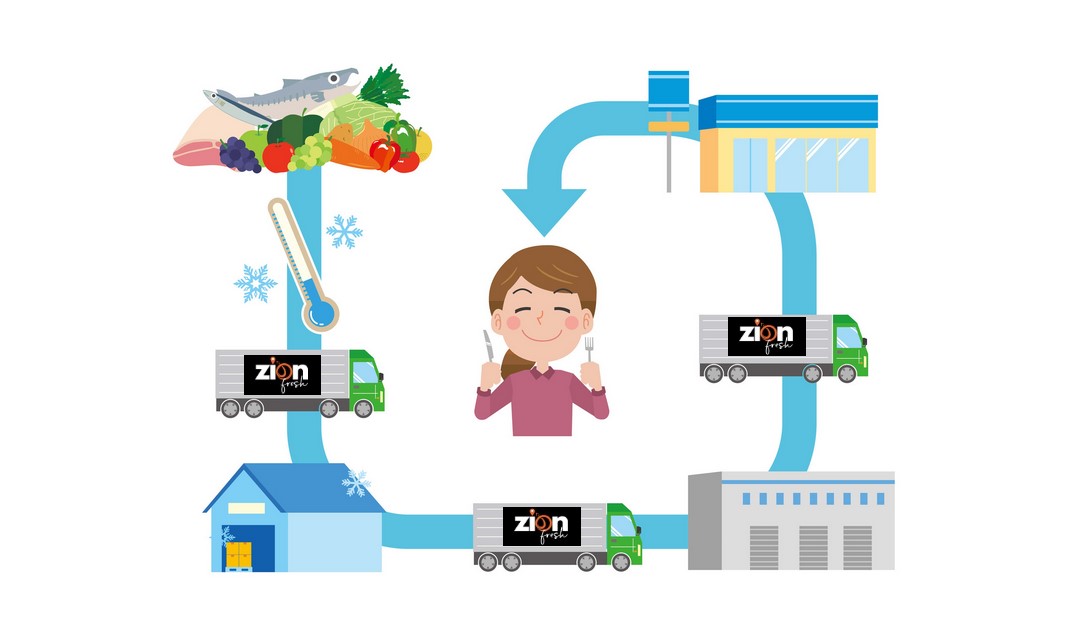

A successful cold chain eventually ensures the maintenance of the desired states of sensitive products from start to finish throughout the logistics process. In contrast, failure to do this can result in degradation, bruising, discolouring and microbial growth.

And here’s where the very concept of efficient cold chain management comes into play!

Efficient cold chain management- why necessary?

The cold chain process involves performing a chain of tasks to prepare, store and transport products. Suppose the temperature drops in any sector of the whole chain process, the quality of the goods could be thrown away. And failing to maintain optimal temperature can lead to many undesirable outcomes, such as product degradation and financial implication to end-user consumer discontent.

The management process includes the storage, packaging, transportation, product management, and secure and safe delivery of temperature-sensitive goods and products. You can expect your product to be delivered without bruising, bacterial growth, disarrangement and any worse while preventing product waste, damage or loss. Also, cold chain management enables efficiency as it uses integrated tracking and monitoring in refrigerated transport services.

So no matter whether in transit, in storage or in the display, for the products requiring cold chain solution, efficient cold chain management is an essential component. And it is definitely a critical success factor for everyone involved in the whole system, from the manufacturer to the shipper to the end user.

Top practices to build a better cold chain

Dealing with a temperature-controlled supply chain is not an easy feat when there are many components to deal with. But by adopting the supply chain best practices, one can easily avoid any sort of disruption in cold chain shipment management. So here are some key considerations you can try on for a dependable cold chain.

Start considering the supply chain needs early

When you are just starting out, it is necessary to plan the components of your cold supply chain early. You need to correctly forecast what the customers require, the ideal temperature needs of your goods and products, and all about the warehouse efficiency, material sources, and packaging requirements prior. Also, it is crucial to consider the logistics partners or companies you will take refrigerated transport services from and match their service with your temperature-control requirements. Then, when it comes time for storage, shipment or delivery, all these detailed records will end up saving you time and money.

Select a logistics company wisely

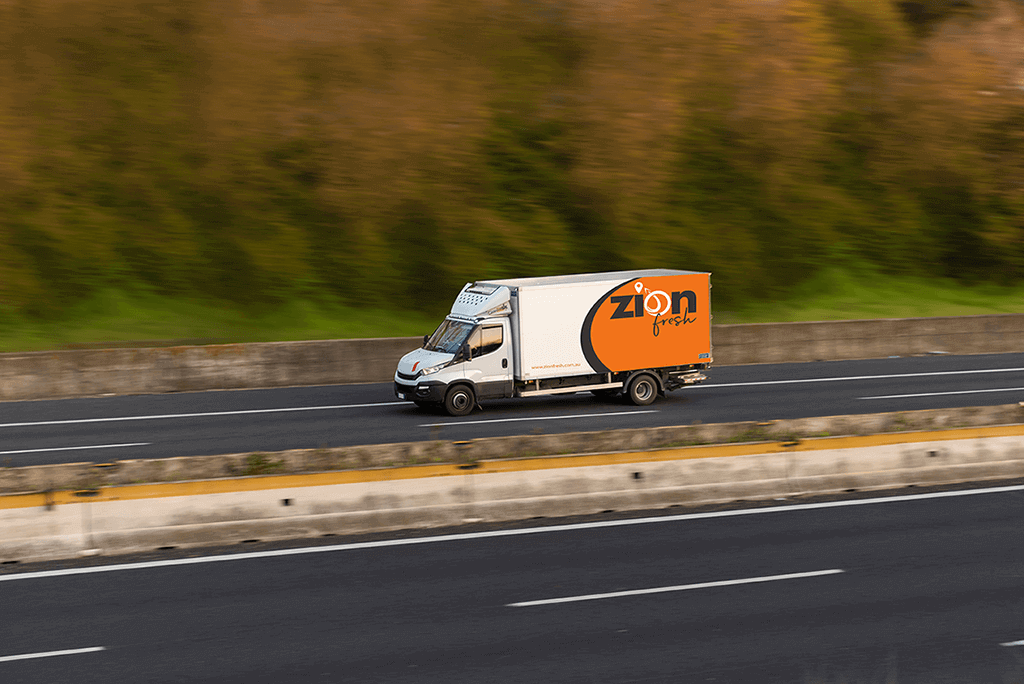

In cold chain management, logistics requires great attention to ensure the products hit their final destination at the right temperature. That is why choosing a reliable, efficient and innovative logistics company like Zion Fresh should top the priority list. Suppose you are seeking refrigerated transport in Melbourne; look for a company that offers you a complete suite of transportation capabilities with an all-in-one solution for moving temperature-sensitive products. Check whether they have a system in place for real-time tracking of location and temperature, and ask whether they meet your temperature control requirements for your products or not. Also, consider cost, performance, coverage, terms and experience in logistics selection.

Adopt cost-reduction strategies

You need to understand the cold chain and the logistics cost, which includes transportation, staff labour, inventory storage and other administrative expenses. Reducing expenses across all of these operations can eventually impact your bottom line. But due to the lack of end-to-end supply chain visibility, you might end up facing product waste, high cost or delivery delays. Hence to reduce excess cold chain management costs, you need to implement cost-cutting strategies. And you can do it by embracing automation in your data processing and operational system. Work with a third-party logistics provider to eliminate waste and other redundancies, and outsource any specialised refrigerated transport service provider to minimise transportation costs.

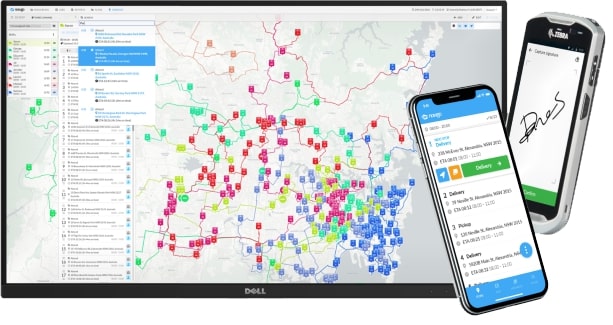

Adopt modern tracking technology

A robust cold chain includes digital technology to track, manage and improve logistics in the supply chain as well as to provide transparency and confidence in customer service. To integrate technology to make the inventory process much smoother and more efficient. As the supply chain depends upon networks of a digital system, the necessity of strengthening cyber security ranks high. So pick technologies that will mitigate any possible risks. You can introduce an automated, contactless payment solution and enable automation in the warehouse and distribution process. Also, adopt the best kind of monitoring systems like live GPS and tracking devices.

Share responsibility when loading and unloading

It is wiser to make sure that the shippers and carriers are sharing tasks when loading and unloading. Shippers and carriers need to bear the responsibility of maintaining outdoor and indoor temperatures as well as the working condition of the truck or container. Otherwise, if an item sits outside a temperature-controlled environment for a longer time needed to load and unload the palettes, the products can be rejected. So while accepting any loading, carriers must double-check the temperature. Then shippers must monitor the airflow in the transport to ensure that there is enough space for air to pass between walls, pallets, ceiling and floor.

Follow sustainable practices

The cold chain usually operates using a highly complex network and infrastructure, which require several refrigeration components. So you can give try to bring sustainability into the process. For example, to minimise your carbon footprint, you can look for cold storage facilities with energy-efficient cooling systems and low-carbon transport networks. Also, you can practice sustainable cold chain packaging, which is recyclable and eco-friendly.

Ensure proper training for employees

In order to maximise employee efficiency and minimise safety incidents, you must provide your employees with enough training to prepare them with all the skills needed. The training can be done in various types. Suppose the safety training is crucial for the employees, where you can cover any of the topics including basic hazard recognition or slips, trips and falls. Then to keep your employees up to date with the industry laws and regulations and create a safer work environment, arrange compliance training. Technical training is also necessary where employees can learn and adopt techniques on stacking, maintenance, vehicle operations, loading and unloading trucks etc.

Most importantly, collaborate more and more

Effective collaboration among the shippers, carriers, vendors, providers and other key holders is crucial to get the right product to the right customer in the right market at the right time. After all, communication is key when it comes to successful cold chain shipment. And to stay on the same page, transparency of shipment information among the internal and external stakeholders is needed. Involve all stakeholders up front in defining roles, expectations and requirements. All this will benefit you with higher inventory turns, lower transportation costs, improved customer service metrics and fast decision-making.

No matter whether you are shipping food, vaccines, or medicines, the cold chain is a vital part. Though there are a number of possible pitfalls that can occur at any stage of the supply chain, more and more investment in infrastructure, expertise, and technology can eventually ensure the safety and quality of perishable goods and items.

From the latest combinations of cooling technologies to trained delivery experts, Zion Fresh has it all under the same roof. By combining all the needed tools and expertise, we offer you to provide personalised service. Contact us today to learn more.